Industrial Safety and Health

T&K TOKA's main production facilities, the Saitama Headquarters and the Shiga Factory, as well as the Osaka Branch, have established legally mandated safety and health committees. The committees include section members from various divisions, including Manufacturing, Technical, Logistics, and Management Division, and identify new areas for improvement by incorporating the perspectives of members other than the department under examination. The committees meet monthly to discuss safety and health, and their members inspect sites and plants quarterly to identify dangerous areas as a way of preventing accidents from occurring.

Within the plant at the Saitama Headquarters, additional actions to ensure safety and health are being implemented through the "5S" (seiri, seiton, seiso, seiketsu, and shitsuke – sorting, arranging, cleaning, sanitation, and discipline) and Total Productive Maintenance (TPM) programs. Quarterly inspections are also carried out at regional offices and plants, which result in a unified, shared recognition of safety and health throughout the Company.

Drill for response to an accident involving leakage

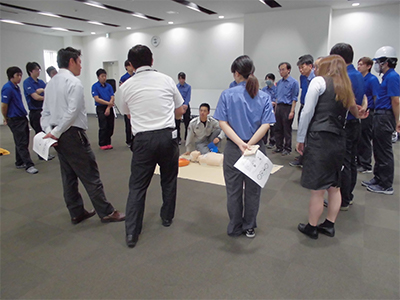

Training on the use of an automated external defibrillator (AED)

Preventing reoccurrences of work-related accidents

In the event a work-related accident occurs, as a mechanism to prevent recurrence, we conduct a thorough investigation at the department where it occurred (asking "why" regarding equipment failure or human error, and searching for the "true cause") and make countermeasures. Countermeasures are evaluated by the safety and health committee for their effectiveness in terms of safety, and this is communicated to the division involved and, through the safety and health committee, to other divisions across the Company.

Selection of new raw materials

In our ink manufacturing, we are working on switching to substances that have less impact on health and the environment, and also conduct training on safe production. When a new raw material has been adopted, we conduct "risk assessment" of operations at each stage of development and production based on the hazard information listed on the safety data sheet. Those results are referred to the management committee through the person responsible for chemical substances management, and measures required for appropriate management are implemented. Risk level is set using five-grade evaluation, and when a production stage is designated as Level 3 or higher, the person responsible explains the potential hazards to the manager of the production division subject to the assessment using an adoption notification, safety data sheet, and assessment report. When the manager of the production division receives a potential hazard notification, they will post it in writing in the department so that all workers are aware of its content. Risk assessment results are posted on the Company's internal network.

Promoting employees' health

Medical examinations

As required by law, the General Affairs Department centrally manages the status of medical examinations for all employees, and for employees whose results require an additional or further examination, the employee's supervisor will instruct the employee to have another examination. In addition, special medical examinations are conducted and results are managed as legally required for workers engaged in work deemed particularly hazardous according to occupational health measures.

Mental health care

Stress checks have been legally required since December 2015. We coordinate the checks for all employees and arrange consultations with industrial physicians for persons with high stress levels who wish for such intervention.

Industrial safety and health data

| Number of deaths and injuries due to industrial accidents | Cumulative hours worked | Number of days leave was taken | Frequency rate | Aggregated number of work-days lost | Severity rate | |

|---|---|---|---|---|---|---|

| 2017 | 6 | 1,528,004.25 | 100 | 3.92 | 82 | 0.053 |

| 2018 | 1 | 1,582,212.25 | 1 | 0.63 | 0 | 0 |

| 2019 | 3 | 1,502,773.83 | 39 | 1.99 | 32 | 0.021 |

| 2020 | 0 | 1,384,156.75 | 0 | 0 | 0 | 0 |